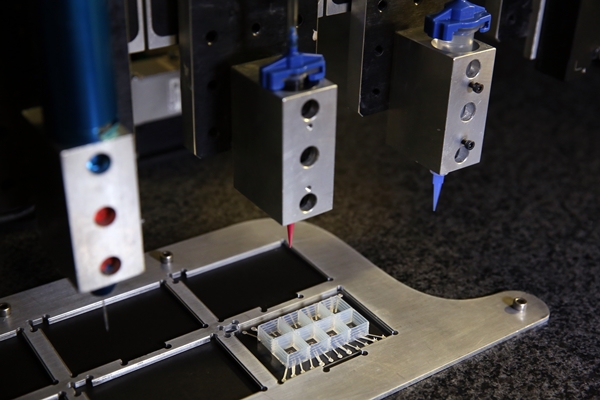

3-D printer combining multiple material streams for organ-on-chip devices (Johan Lind and Lori K. Sanders, Harvard University)

24 October 2016. Biomedical engineers at Harvard University developed a programmable and automated process for creating miniature organs on chips with integrated sensors using 3-D printing. The team from Harvard’s engineering school and Wyss Institute for Biologically Inspired Engineering describes the process and its first application, a miniaturized heart-on-a-chip, in today’s issue of the journal Nature Materials (paid subscription required).

Organs-on-chips simulate biological processes and structure with human cells and tissue integrated into miniature chip devices with tiny channels for fluids to flow that can be observed and measured in the lab. These devices make it possible to more systematically study drug effects on organs and assess for toxins than conventional tests with live animals. Wyss Institute researchers are developing several organs-on-chips including simulated lungs, hearts, tongues, and intestines.

Creating these devices today requires a laborious process for individual design and fabrication, with complex chip lithography guided by cameras on microscopes in semiconductor clean rooms. Researchers on this project led by engineering and Wyss Institute faculty Kit Parker and Jennifer Lewis are seeking a faster, programmable, and automated process for designing and building these organ chips that can make them more customized for individual patients. In addition, the team wants to a more seamless method of integrating sensors into the chips that enhances their measurement functions.

The team devised a process with simultaneous 3-D printing of different materials that combine soft strain sensors into the structure of organ tissue. Soft strain sensors combine layers of conductive fluids and polymers in fibers, integrated in this case with cardiac tissue to create a heart-on-a-chip. The researchers devised 6 different ink formulations combining tissue and sensor materials for fabricating the cardiac chip device.

The chip itself, known as a cardiac microphysiological device, has multiple wells for simultaneous assessing various samples of cardiac tissue. The team tested the device with stresses on contracting laminar heart muscle tissue found in the heart walls, as well as responses of drugs on heart muscle tissue derived from stem cells.

“We are pushing the boundaries of three-dimensional printing by developing and integrating multiple functional materials within printed devices,” says Lewis in a university statement. “Our microfabrication approach,” adds Parker, “opens new avenues for in vitro tissue engineering, toxicology, and drug screening research.”

Several Wyss Institute scientists, including institute director Donald Igber, founded the spin-off company Emulate Inc. to commercialize research into organ-on-chip devices. As reported in Science & Enterprise, Emulate Inc. raised $28 million in its second venture funding round in March 2016, which was supplemented last week with another $17 million.

The following video tells more about the 3-D printing process for organs-on-chips.

- Worms-On-A-Chip Drug Screening System Designed

- Challenge Seeks Gastrointestinal Toxicity Test Methods

- Material Developed for 3-D Printed Bone

- Chip Device Speeds Single Cell Analysis

- Chip Device Simulates Blood Vessels in Clotting

* * *

RSS - Posts

RSS - Posts

[…] 3-D Printing Creates Heart-on-Chip with Sensors […]