Materials scientists and engineers at Massachusetts Institute of Technology in Cambridge have developed a process for generating composite materials with customized mechanical properties. The team published its findings last month in the journal Advanced Materials (paid subscription required).

The research, funded by the U.S. Army, started looking into materials that could serve as armor for vehicles and aircraft, while being light in weight, flexible, and energy absorbent. That inquiry led to co-continuous materials, which team leader and postdoc Lifeng Wang says limit crack propagation because of their micro-level structural properties.

Crack propagation is the property of cracks that start small, but then spread through the material and cause extensive damage; cracked car windshields are an example. Because new co-continuous materials can limit crack propagation, says Wang, they are more damage-tolerant, even when subjected to events that cause cracks.

Some current composites add strengthening fibers to existing materials, but the added strength is confined mainly to the direction of the fibers. Even when adding continuous materials, such as resins, that add strength in multiple directions to existing composites, the new continuous materials tend to take over and dominate the properties of the new material.

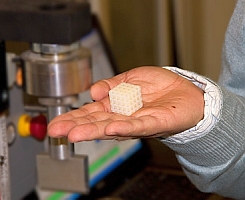

Wang and colleagues experimented with combinations of co-continuous materials, where each material in the mix introduced different sets of properties, and which returned more synergistic results. Among the experiments were a combination of two polymers with different properties.

One polymer resembled glass, in that it had strength and stiffness, but was also brittle. The other material was more like rubber: tough and resilient, but not that strong. By combining the two materials, the team got a material with strength, stiffness, and toughness.

To make the process more applicable to a larger range of materials, the researchers used computer simulations to design materials with various physical properties, and then made and tested samples in the lab. They found the properties enumerated in the computer simulations largely agreed with the later tests in the lab.

Co-author and MIT materials scientist Edwin Thomas says the new fabrication techniques developed in this research can “take to another level” the material development process. While this research focused on materials’ mechanical properties, the researchers say the same principles could be applied to controlling a material’s electrical, thermal, optical or other properties.

Read more: University Studying Smart Polymer Film to Control Substrates

* * *

RSS - Posts

RSS - Posts

[…] Read more: Process Devised for Custom-Made Composite Materials […]

[…] Read more: Process Devised for Custom-Made Composite Materials […]

[…] Read more: Process Devised for Custom-Made Composite Materials […]

[…] Read more: Process Devised for Custom-Made Composite Materials […]

[…] Read more: Process Devised for Custom-Made Composite Materials […]