Researchers at Kiel University and Hamburg University of Technology in Germany have developed a network of porous carbon nanotubes that they say is the lightest material in the world. The research team, which includes a colleague from the Leibniz Institute of Surface Modification in Leipzig, published its findings online in the journal Advanced Materials.

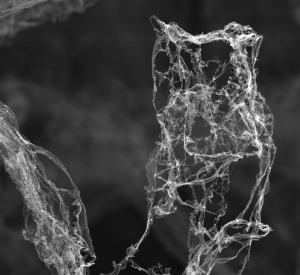

The material, called aerographite, is made from a network of porous carbon tubes, three-dimensionally interwoven at the nano and micro levels. Aerographite weights 0.2 milligrams per cubic centimeter, making it 75 times lighter than Styrofoam, but still remains strong. The material, say the researchers, is colored jet-black, stable, electrically conductive, ductile, and opaque.

Up to now, the lightest material was made of nanoscale nickel tubes, but nickel has a higher atomic mass than carbon. The nanotubes in aerographite also have porous walls, which decreases its weight further.

Among aerographite’s properties is resilience, despite its low weight. Lightweight materials can normally withstand compression but not tension. Aerographite, on the other hand, can be compressed up to 95 percent and pulled back to its original form without any damage. Other materials, say the researchers, become weaker and less stable when exposed to such stress.

The Kiel team started with zinc oxide powder, which when heated to 900 degrees C, becomes crystalline. The Kiel researchers then formed zinc oxide crystals into a pill-shaped skeleton that formed nano- and microscale structures called tetrapods. The tetrapods then interweaved and constructed a network of particles, making the pill-shaped skeleton porous.

The Hamburg team put the tetrapod pill into a reactor, heated to 760 degrees C for chemical vapor deposition. Karl Schulte, a professor in Hamburg’s Institute of Polymers and Composites, describes the the inside of the reactor as “a steaming gas atmosphere that is enriched with carbon,” which adds a coating of a few atomic layers of carbon to the zinc oxide skeleton. At the same time, hydrogen is introduced, which reacts with the oxygen in the zinc oxide to form steam and zinc gas, leaving the aerographite in a network of interwoven tubes.

The properties of aerographite can be manipulated further say the researchers. “The faster we get the zinc out, the more porous the tube’s walls get and the lighter is the material,” says Hamburg’s Matthias Mecklenburg.

One application of aerographite is in lithium-ion batteries, which could reduce the weight of the batteries, making them more useful for small cars and powered bicycles. Other applications include adding electrical conductivity to plastics, electronics for aviation and satellites, and in water purification.

Read more:

- Boron Added to Carbon Nanotubes Produce Super Oil Sponge

- Aqueous Solution Tested to Reduce Carbon Nanotube Toxicity

- Stretchable Sensory Material Created with Carbon Nanotubes

- Solid-State Supercapacitor Created with Carbon Nanotubes

* * *

RSS - Posts

RSS - Posts

[…] Scientists Produce Ultralight Carbon Nanotube Material […]

[…] Scientists Produce Ultralight Carbon Nanotube Material […]