Engineers in Korea developed a process for printing cheap electronic devices on every day items that can transmit data to smartphones. The work of the authors from Sunchon National University and Paru Printed Electronics Research Institute is described in the journal Nanotechnology (free registration required), published by Institute of Physics.

Engineers in Korea developed a process for printing cheap electronic devices on every day items that can transmit data to smartphones. The work of the authors from Sunchon National University and Paru Printed Electronics Research Institute is described in the journal Nanotechnology (free registration required), published by Institute of Physics.

The team led by Jinsoo Noh and Gyoujin Cho developed a device they call a rectenna that uses near-field communication protocols similar to those used today by smartphones for financial transactions. The rectenna is a combination of an antenna and rectifier that converts alternating current into direct current. The device harnesses power directly from radio waves given off by a mobile phone, converting alternating to direct current.

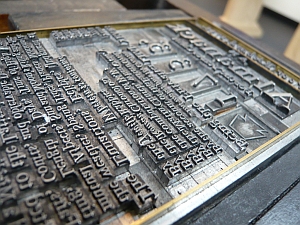

The researchers devised a gravure-style process for printing rectennas, where an image is etched into a plate or cylinder and filled with ink, which is transferred to the printed substrate, similar to commercial gravure printing used in long-run catalogs and magazines. The team test four different nanoparticle-based electronic inks printed on plastic foil substrates. This roll-to-roll process, say the authors, makes it possible to produce rectennas at about a penny ($0.01) each.

The rectennas would work like familiar quick-response (QR) codes that can be scanned by smartphones to capture data in the code. But unlike QR codes, rectennas can be printed into existing images, such as logos or on price tags, without taking additional space. As programmable chips, rectennas can also contain more data and perform more functions than QR codes.

“What is great about this technique,” says Gyoujin Cho, “is that we can also print the digital information onto the rectenna, meaning that everything you need for wireless communication is in one place.” He anticipates the technology can benefit the medical, automotive, military, and aerospace industries.

Read more:

- Simple Process Devised to Make Thin-Film Display Material

- New Study to Examine Next Generation Mobile Networks

- Manufacturing Process Devised for More Economical LEDs

- Engineers Develop Efficient Nanotech Solar Energy Film

Photo: purdman1/Flickr

* * *

RSS - Posts

RSS - Posts

You must be logged in to post a comment.