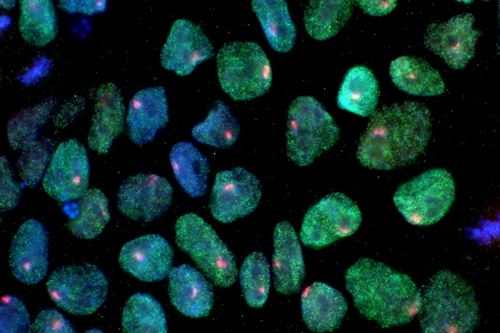

Induced pluripotent stem cells reprogrammed from human skin (California Institute for Regenerative Medicine)

15 July 2016. An academic-industry team in Europe designed and tested new processes that can simplify and streamline production of human stem cells in large quantities. Researchers from Uppsala University in Sweden, University of Nottingham in the U.K., and GE Healthcare in Uppsala reported on this innovation on 13 July in the journal Nature Communications.

Health care providers, research labs, and drug companies are increasing their use of human pluripotent stem cells for regenerative medicine, tissue engineering, and drug screening, as well as therapeutic uses in the clinic. These stem cells can develop and transform into a wide range of mature cell types in the body, but current culturing processes for growing and reproducing stem cells are too expensive to scale-up to large quantities, or do not easily support advanced applications, such as cloning.

The search for more efficient stem cell production processes began in the lab of molecular biologist Cecilia Annerén at Uppsala University, who is also marketing manager for cell cultures at GE Healthcare in Uppsala. Sara Pijuan-Galitó, who led the project, started the study as a postdoc in Uppsala, and continues the work now as a research fellow at Nottingham’s stem cell biology group.

Pijuan-Galitó and colleagues began with a commercially-available stem cell culture medium called Essential-8, which is not derived from other animal components, known-as xeno-free, or other feeder cells that may carry viruses to contaminate the stem cells. The team then supplemented Essential-8 with inter-alpha-inhibitor, an abundant protein in blood, already tested as a treatment for inflammation and other disorders.

For the researchers, however, inter-alpha-inhibitor has another desirable property: it activates cell differentiation pathways for transformation into multiple adult cell types, as shown previously in tests with stem cells from mice. In lab tests, the team found that adding inter-alpha-inhibitor to Essential-8 provided a culturing medium that induces attachment and growth of both human embryonic and adult pluripotent stem cells.

The key benefits of combining inter-alpha-inhibitor and Essential-8, however, are that it can grow and differentiate stem cells on plain lab plastic surfaces, without bioactive coatings, as well as support cloning tasks. Moreover, it can improve the survival of stem cells in harsh conditions. “It is the first stem cell culture method that does not require a pre-treated biological substrate for attachment,” says Pijuan-Galitó in a Nottingham statement, “and therefore, is more cost and time-efficient and paves the way for easier and cheaper large-scale production.”

Annerén adds, “As coating is a time-consuming step and adds cost to human stem cell culture, this new method has the potential to save time and money in large-scale and high-throughput cultures, and be highly valuable for both basic research and commercial applications.”

GE Healthcare has more than a passing interest in stem cell production. On the same day the paper appeared, GE Healthcare announced the acquisition of Biosafe Group SA, a supplier of cell bioprocessing systems. In April, GE and Mayo Clinic formed a joint venture known as Vitruvian Networks to develop software and manufacturing systems supporting cell and gene therapies.

Read more:

- Engineered Facial Bone Grown from Stem Cells

- Consortium Aims to Upgrade Cell Manufacturing

- Patent Awarded for Skin Stem Cell Regeneration Methods

- FDA Approves Trial Testing Stem Cells for Brain Injuries

- Challenge Seeks New Regenerative Tools with Stem Cells

Disclosure: The author owns shares in GE.

* * *

RSS - Posts

RSS - Posts

You must be logged in to post a comment.