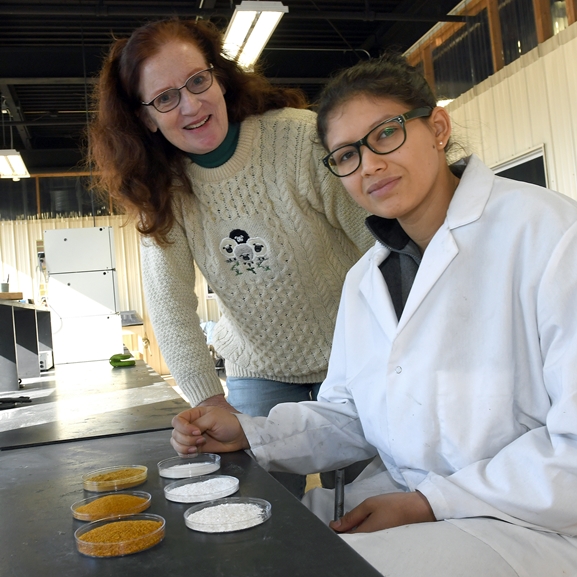

Katrina Cornish, left, and Cindy Barrera examine ground tomato skins and egg shells. (Kenneth Chamberlain, Ohio State University)

7 March 2017. Agricultural scientists in Ohio are developing a process for converting common food waste into materials used in car tires, and filed a patent for these techniques. The lab of biomaterials professor Katrina Cornish at Ohio State University also started a spin-off enterprise to commercialize their discoveries for producing rubber products from alternative sources.

Cornish and colleagues study the production of bio-based materials that can substitute for imported rubber, a vital material for a wide range of consumer and industrial goods. Natural rubber, however, is derived largely from one plant species, Hevea brasiliensis, native to South America and grown commercially as well in southeast Asia and west Africa. Cornish’s lab cites data showing that the U.S. could face a shortfall of 1.5 metric tons of imported rubber by 2020, due largely from increasing global demand, creating a need for domestic raw material sources.

Researchers in the lab are already investigating methods for converting common plants and even those considered weeds growing in North America into raw materials for rubber. Among those materials are guayule, a flowering plant in the southwestern U.S. and Mexico,. Cornish and colleagues are developing guayule into an alternative for latex rubber used in stretchable products like gloves and condoms. In addition, attempts to make rubber from dandelions go back as far as the early 20th century, but Cornish’s lab is studying a variation of a dandelion native to Kazakhstan in central Asia that they call Buckeye Gold, which has roots that can produce rubber nearly identical to Hevea plants.

As part of these studies, the researchers are also looking into replacements for additives used in making rubber products, such as car tires. About 30 percent of the content of car tires is carbon black, a derivative of carbon made from heavy oil or natural gas into particles that mix with rubber to improve its durability and give tires their black color. And just as the need for natural rubber is growing with the expanding world economy, the need for carbon black is growing as well, thus the need for domestic alternatives.

Cornish’s lab discovered alternatives to carbon black that provide durability for tires in common waste items from food, such as egg shells and tomato skins. Research by Cindy Barrera, a postdoctoral fellow in the lab, shows egg shells have a porous microstructure that offer a larger surface area to bind with rubber molecules, while tomato skins are stable at high temperatures, a key property for tires. Both egg shells and tomato skins are available in large quantities as waste items from food products manufacturers.

“Fillers generally make rubber stronger, but they also make it less flexible,” says Barrea in a university statement. “We found that replacing different portions of carbon black with ground egg shells and tomato peels caused synergistic effects — for instance, enabling strong rubber to retain flexibility.” Colleagues in the lab are studying other additives to keep tires black in color, rather than the reddish-brown hue from egg shells and tomato skins.

Ohio States technology transfer office filed for a patent on processes to replace carbon black and other additives with natural products, such as food wastes. Cornish and Barrea are among the inventors listed on the document. Cornish is also the founder of the company EnergyEne in Wooster, Ohio licensing the rights to this patent from Ohio State for commercial development. EnergyEne is already developing commercial techniques for deriving latex rubber from guayule plants, and received a small business technology transfer grant from National Science Foundation to support its work.

More from Science & Enterprise:

- Solar Reactor Devised for Small-Scale Chemical Production

- Algae Feed Proposed to Enrich Farm Salmon Fatty Acids

- Spinach Enhanced to Detect Chemicals, Send Signals

- Small Business Grant Funds Natural Dyes Crop Research

- Process Devised for Plastics from Carbon Dioxide, Plants

* * *

RSS - Posts

RSS - Posts

You must be logged in to post a comment.