14 July 2017. Two graduate students in materials science and engineering designed and tested an artificial heart made with soft plastics for eventual use as an implanted device. The doctoral candidates, from the university ETH Zurich in Switzerland describe the device and test results in the 10 July issue of the journal Artificial Organs (paid subscription required).

The doctoral students — Nicholas Cohrs in materials science and Anastasios Petrou in engineering — with colleagues from their respective functional materials and product development labs, are seeking to improve on artificial heart pumps that provide temporary cardiac functions for people with heart failure and others waiting for a donor’s heart to transplant. Current external heart pumps, say the authors, are complex mechanical devices with a number of points susceptible to error or failure. The university says some 26 million people worldwide suffer from heart failure, but there’s a shortage of donated replacement hearts.

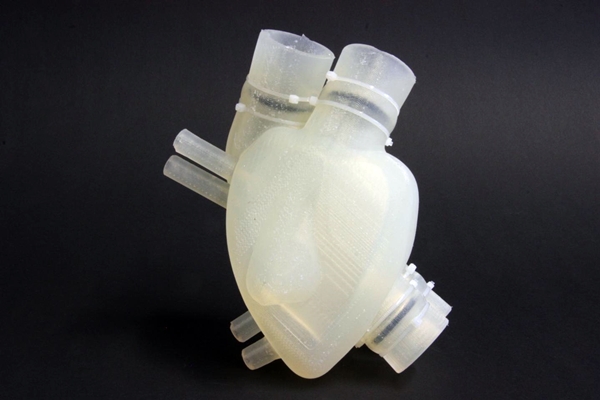

In a university statement, Cohrs says the research team’s goal, “is to develop an artificial heart that is roughly the same size as the patient’s own one and which imitates the human heart as closely as possible in form and function.” The device is made from rubber-like silicone, a material now used in a variety of medical devices. The team built the device with 3-D printing, adapting a method from an artisan’s technique called lost wax casting that begins with wax model.

The Zurich artificial heart is basically one piece of silicone with a detailed internal structure that weighs 390 grams (0.86 pounds). The device has left and right ventricles, like a real human heart, with a third chamber between the two ventricles. This third chamber inflates and deflates with pressurized air pumped in, replacing heart muscle contractions.

The team tested the Zurich artificial heart in a simulated circulation system using fluids with the same physical properties as blood. The device achieved a fluid flow of 2.2 liters per minute at a rate of 80 beats per minute. The researchers say the device generated physiological signals of blood flow and pressures by emulating real heart actions. However, the device was able to operate for 3,000 beats, the equivalent of 30 to 45 minutes, before its material started to fail.

“This was simply a feasibility test,” notes Cohrs. “Our goal was not to present a heart ready for implantation, but to think about a new direction for the development of artificial hearts.” The team plans to work on improving the tensile strength and long-term performance of the material.

The following video tells more about and demonstrates the artificial heart.

- 3-D Printed Patch Helps Grow New Blood Vessels

- Phones, Algorithms Boost Adherence to Stroke Meds

- Company, NC State Partner on Tissue Oxygen Patch

- EU Project to Develop More Versatile Heart Pacemakers

- Solar Cells Shown Feasible to Power Medical Implants

* * *

RSS - Posts

RSS - Posts

You must be logged in to post a comment.