– Contributed content –

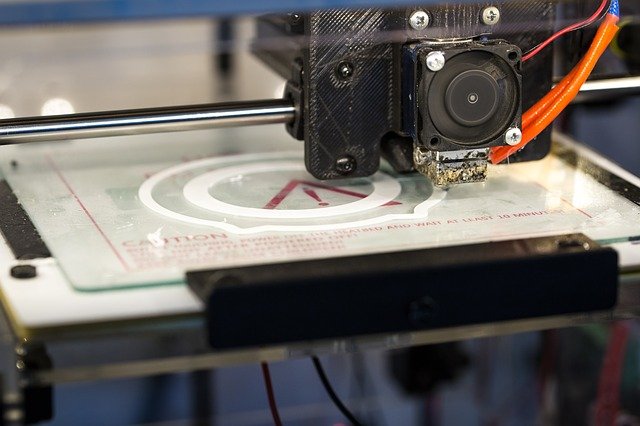

5 Jan. 2021. 3D printing is one of the most exciting new technologies developed in the last decade. Although there are still some limitations, the complexity of the structures we can print and the materials that we can use in 3D printers is always changing. These advances in 3D printing technology are already having a significant impact on industry because they allow for the manufacture of parts in a fraction of the time. In time, it’s likely that most industries will benefit from 3D printing in some way, but these are some of the areas that will be impacted the most.

The medical industry

When you think of 3D printing, you probably imagine plastic objects, but techniques have actually been developed to print living tissue, and this has the potential to completely transform the medical industry. Being able to print replacement organs, for example, would vastly improve the chances of survival for patients awaiting a transplant. Although this technology is in its early stages, it is set to have a big impact once it becomes widespread. 3D printing is also being used in the manufacture of medical devices, making it cheaper and quicker to produce them.

3D printing has also been a huge driving force behind new dental technologies and procedures. For example, many dentists are already 3D printing crowns or models of patient’s teeth so they can produce replacements a lot faster. In the past, people would be waiting weeks or even months for replacement teeth or crowns but this has been drastically reduced by the advent of 3D printing.

Aerospace manufacturing

Designing and manufacturing aircraft, whether manned or unmanned, is an incredibly long and expensive process. An aircraft is made up of so many tiny parts and it’s vital that they are all perfect. This creates a lot of issues when testing and tweaking designs because it takes time to keep making new parts and testing them, and it comes at an added cost. This is why aerospace manufacturing benefits from 3D printing so much because parts can be printed in no time and it’s so simple to make adjustments. This means that the design process is far more streamlined and aerospace companies can save themselves a lot of money.

Architecture

Creating scale models is an essential part of the design process for architects, but it can be very time consuming. But a 3D printer can create those models in a fraction of the time, without the cost of labor. You can also ensure complete accuracy when using a 3D printer, so models will always be perfectly to scale. Not only will this save time and money, but it will also open up new possibilities and allow architects to design more ambitious buildings, with the help of 3D printed models to make sense of their drawings. There have even been prototype buildings that are entirely 3D printed and even though this is not a widespread practice, it could eventually change the way that construction works forever.

Although 3D printing is still a relatively new technology, it has already changed the way that these industries work forever. In the future, it is likely that we will see big changes in other industries and the way that we manufacture products will be entirely different from what it is now.

* * *

RSS - Posts

RSS - Posts

You must be logged in to post a comment.