16 August 2017. Researchers in the U.K. devised 3-D printing techniques for human and animal cells to produce functioning tissue with multiple types of cells. A team from the universities of Oxford and Bristol describe the process in the 1 August issue of the journal Scientific Reports.

Researchers led by Oxford biochemistry professor Hagan Bayley are developing methods for producing replacement tissue for regenerative medicine with 3-D printing that better emulate the original tissue. Bayley founded the company OxSyBio, short for Oxford Synthetic Biology, that licenses the technology and is taking the process to market. Several co-authors of the Scientific Reports paper, including first author Alexander Graham are now employed by OxSyBio.

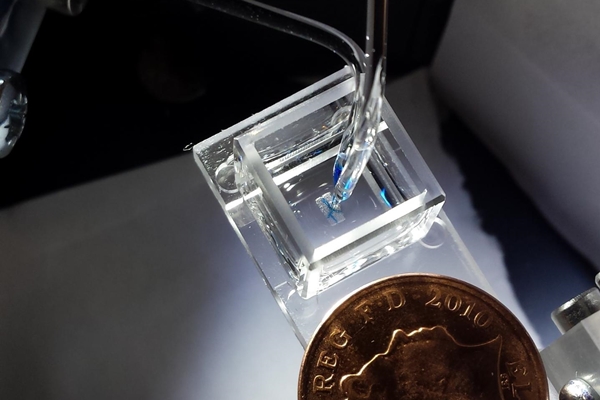

Graham, in an Oxford University statement notes that up to now, 3-D printing is not able to produce the complex details found in human tissue. “To date, there are limited examples of printed tissues,” says Graham, “which have the complex cellular architecture of native tissues. Hence, we focused on designing a high-resolution cell printing platform, from relatively inexpensive components, that could be used to reproducibly produce artificial tissues with appropriate complexity from a range of cells including stem cells.”

Bayley and colleagues earlier devised techniques, published in the journal Science and reported in Science & Enterprise, for assembling layers of water droplets and lipids, or natural oils, into tissue-like networks with the potential for replacing damaged tissue in humans. In the new study, the team took that process further, producing water and lipid droplets at a higher resolution and density, while printing two different types of cells in one sample and improving the cells’ survivability.

The 3-D printing techniques produced droplets as small as 1 nanoliter, or 1 billionth of a liter, containing human embryonic kidney cells and mesenchymal stem cells from sheep, which transform into bone, muscle, or fat tissue. In tests of the technique, the researchers produced cellular samples with details under 200 micrometers (0.008 inches). The samples include junctions between cells and connections like those between cartilage and bones.

In addition, the team found after printing, 9 of 10 cells on average survive, and 2 types of human embryonic kidney cells printed together can proliferate and grow together in lab cultures. Still another test shows printed mesenchymal stem cells from sheep can transform over 5 weeks into a life-like material containing collagen similar to cartilage in joints and that connects to bones.

Co-author Sam Olof, now the chief technologist at OxSyBio, expects “it will be possible to create personalized treatments by using cells sourced from patients to mimic or enhance natural tissue function. In the future, 3-D bioprinted tissues may also be used for diagnostic applications, for example, for drug or toxin screening.”

More from Science & Enterprise:

- Synthetic Beating Heart Repair Tissue Being Developed

- Genetic Techniques Speed Brain, Muscle Cell Production

- Tissue Regeneration Start-Up Gains $33M in Early Funds

- Neurology Drug Signals Shown to Help Tooth Repair

- Gene Expression Changes Found in Wound Healing Therapy

* * *

RSS - Posts

RSS - Posts

[…] 3-D Printing Process Developed for Living Tissue […]