20 February 2014. An international team of materials scientists and engineers developed high-strength artificial muscles from materials found into ordinary fishing line and sewing thread. The consortium from University of Texas in Dallas, University of British Columbia in Vancouver, Canada, and colleagues from China, Turkey, Australia, and Korea published their findings today in the journal Science (paid subscription required).

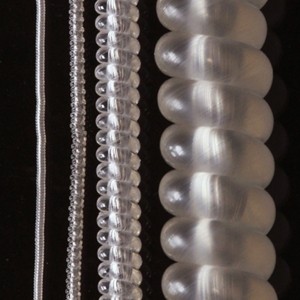

The team led by Ray Baughman, director of Dallas’s NanoTech Institute, developed the artificial muscles by twisting polymer and nylon fibers of various sizes until they reach a tightly coiled state, much like a highly twisted rubber band. Subjecting these coils to heat produces a muscle-like response where the materials contract dramatically, then relax to their original length when cooled.

Tests of the fibers wound into artificial muscles showed the muscles could contract up to 49 percent, compared to about 20 percent for human muscle. Tests also showed the artificial muscles could lift loads more than 100 times the same length and weight of human muscle. In addition, the coiled muscles could generate 5.3 kilowatts of mechanical work, which by weight is comparable to a jet engine.

When woven into textiles, the researchers showed the fibers could change porosity when subjected to changes in ambient temperatures. Baughman’s team demonstrated these properties in simulated window shutters that automatically opened and closed in response to outdoor temperature.

The authors expect these artificial muscles to have a wide range of applications. Textiles woven from these muscle fibers could manufactured into clothing for firefighters that protect the wearer in intense heat, while relaxing to more normal weaves in cooler temperatures. Other uses include fibers for controlling robotics, such as those used in surgery, as well as exoskeleton and prosthetic devices.

University of Texas in Dallas applied for U.S. provisional and international patents for the invention.

The following brief video, courtesy of University of British Columbia, shows a demonstration of the muscle fibers in a simulated surgical forceps.

- Metal-Organic Framework Developed that Responds to UV Light

- New Process Speeds 3-D Printing of Multiple Materials

- Small-Scale Ceramics Materials Engineered for Flexibility

- NIH Funding Micro-Sutures for Stem Cell Heart Muscle

- Gold Nanoparticles Configured into Stretchable Conductors

* * *

RSS - Posts

RSS - Posts

You must be logged in to post a comment.