22 December 2016. An engineering group developed a solar-powered catalytic reactor that can produce small amounts of drugs and agricultural chemicals on demand. A team from the lab of chemical engineering professor Timothy Noël at Eindhoven University of Technology in the Netherlands describe their system in the 22 December issue of the journal Angewandte Chemie (paid subscription required).

Noël and colleagues are seeking sustainable and economical methods to produce medications that can overcome barriers of distance and logistics. Chemicals for drugs today are often produced with fossil fuels and toxic chemicals, and must be made in large batches to be economical, thus the search for alternative processes. Noël’s research group in Eindhoven studies chemical catalysts that connect synthetic chemistry to engineering to overcome these obstacles.

One of the lab’s projects is the capture of energy from sunlight, which while abundant is also too low in power to trigger the kinds of reactions needed to produce even small amounts of chemicals. The researchers’ solution was modeled after photosynthesis, the natural process used by plants to capture sunlight for production of sugar, in a device they call an artificial leaf.

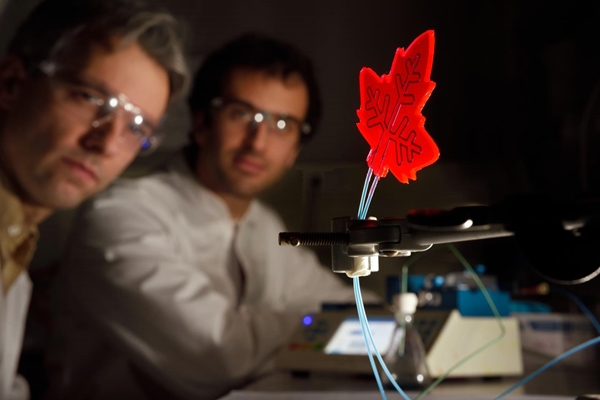

The artificial leaf — the team’s prototype reactor is shaped like an actual leaf — combines techniques for capturing and amplifying sunlight with continuous flow chemistry to generate the desired chemical reactions. To capture energy from the sun, the researchers devised materials known as luminescent solar concentrators, or LSCs, that work like leaves in that they use antenna molecules to attract the light, but add fluorescent dyes to absorb light into the leaf and guide the light toward the edges.

The leaf itself is made of polydimethylsiloxane, a common inert, non-toxic polymer found most famously in Silly Putty for children. The leaf also has tiny channels etched into its surface that allows for the flow of liquids. With computer modeling, the team optimized the leaf’s process to maximize energy production while maintaining its simple design.

The researchers tested the artificial leaf reactor in simulations with LED bulbs, but the real test was using the device outside in normal daylight. The team found the artificial leaf can produce 40 percent higher yields, even on cloudy days, compared to a comparable device without LSCs. The artificial leaf also performs with more stability than the non-LSC device, which experiences more fluctuations in its output. The researchers attribute these performance differences to the artificial leaf’s ability to operate with direct or diffused light, while the non-LSC device needs direct light to work.

The Angewandte Chemie paper reports the team’s proof of concept, but it also provides a pathway for further development. “We still see plenty of possibilities for improvement,” says Noël in a university statement. “We now have a powerful tool at our disposal that enables the sustainable, sunlight-based production of valuable chemical products like drugs or crop protection agents.”

The following video tells more about the project.

- Algae Feed Proposed to Enrich Farm Salmon Fatty Acids

- DoD Grant Funds Exosome Manufacturing Process

- Synthetic Viruses in Gene Therapy Licensed for Production

- Portable On-Demand Biologic Production System Designed

- High-Volume, More Efficient Stem Cell Production Developed

* * *

RSS - Posts

RSS - Posts

You must be logged in to post a comment.