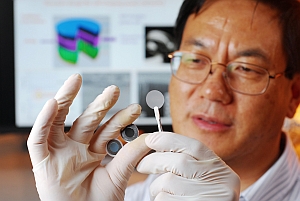

Researchers at Georgia Institute of Technology in Atlanta developed a single device that converts mechanical energy directly into chemical energy, and stores the power until released as an electrical current. The Georgia Tech team led by materials scientist and engineer Zhong Lin Wang (pictured right) published its findings earlier this month in the journal Nano Letters; paid subscription required.

The hybrid generator/storage unit is based on a membrane that drives lithium ions from one side of the cell to the other when the membrane is deformed by mechanical stress. This piezoelectric effect — where electricity is generated when a material is stressed — has been able to generate enough power from activities like walking to generate enough energy for small hand-held devices. In addition to walking, mechanical energy for piezoelectric effects can come from the action of car tires on pavement, or from harnessing ocean waves or mechanical vibrations. The problem has been the ability to store that power for later or stationary use.

The coin-sized unit developed at Georgia Tech has a cathode made of lithium-cobalt oxide and anode of titanium dioxide nanotubes grown on a titanium film. The two electrodes are separated by a membrane made from poly(vinylidene fluoride) film, which generates a piezoelectric charge when placed under strain. When the power cell is mechanically compressed, the film generates a piezoelectric effect that drives the lithium ions from the cathode side of the unit to the anode side. The energy that results is then stored in the anode as lithium-titanium oxide.

Compression of the power cell charges the unit, until the chemical equilibrium of the two electrodes is re-established and the distribution of lithium ions can balance the piezoelectric fields in the film. When the mechanical force is released, the lithium ions remain at the anode. When power is taken from storage by an electrical device, lithium ions inside the cell flow back from the anode side to the cathode side.

Wang’s team has built and tested some 500 of these units, which he estimates will be five times as efficient at converting mechanical to chemical energy as a system with separate generator and storage units. He notes that one way of increasing the device’s efficiency is to improve the case, now made of stainless steel. “When we improve the packaging materials, we anticipate improving the overall efficiency,” says Wang. “The amount of energy actually going into the cell is relatively small at this stage because so much of it is consumed by the shell.”

Read more:

- Scientists Produce Ultralight Carbon Nanotube Material

- Researchers Develop Battery Components as Painted Layers

- Graphene Electrodes Developed for Supercapacitors

- Solid-State Supercapacitor Created with Carbon Nanotubes

- Army Seeking Energy Harvesters for Foot Soldiers and Squads

* * *

RSS - Posts

RSS - Posts

[…] Power Cell Converts and Stores Energy in Single Unit […]