26 Nov. 2018. A bioengineering lab at University of Arizona is researching new techniques with three-dimensional printing, stem cells, and sensors to repair severe bone fractures. The project in the orthopedic research lab of Arizona engineering and medical professor John Szivek is funded by a 5-year, $2.03 million grant from the U.S. Department of Defense.

Szivek’s lab in Tucson studies regenerative technologies to repair bones and cartilage with 3-D printing and stem cells, but also sensors built into the repairs to monitor regeneration of new tissue. The new project aims to develop techniques for repairing severe musculoskeletal trauma, which DoD says is one of the most common disabling injuries in military service, where more than half (54%) affect extremities. In many cases, surgery is required to repair the injuries, but even with surgery, healing is slow and long-term prognosis is often poor. In many cases, amputation and prosthetic devices are the only options.

“Imagine an impact that causes half of a long bone to shatter so that it can’t be put back together,” says Szivek in a university statement. “No current surgical treatment can ensure that kind of injury will heal. This is a really big problem for the military, where explosions or combat injuries can cause big bone defects.”

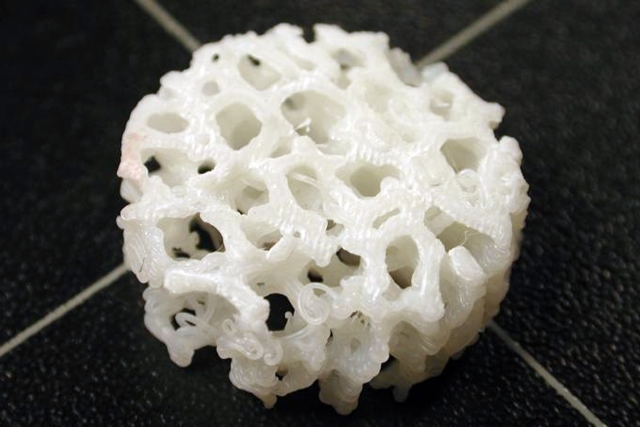

Svizek and colleagues plan to produce 3-D printed personalized plastic scaffolds, based on a computed tomography or CT scans from patients. The scaffolds, acting as a framework, are then seeded with mesenchymal or adult stem cells from the patient’s fat tissue, along with calcium particles, from which new bone tissue can form. Added to the scaffold, stem cells, and calcium particles are implanted electronic sensors that provide real time feedback on healing progress and guide rehabilitation. The sensors can also provide warnings of potential failure of the regenerated bone before a catastrophic event occurs.

The researchers described an early form of this technique in a paper published in March, where they tested the process in sheep, and succeeded after 6 months in producing 41 percent more bone deposition on the scaffolds than animals with scaffolds only implanted. In the new project the team aims to speed up that process, adding exercise to the therapy. “Studies have shown that exercise makes your bones grow, so maybe we can make bone on our scaffolds grow even faster with exercise,” notes Szivek.

Speed is important, says Szivek, because the body’s regenerative capabilities starts to wane over time. “That’s why we need to develop a way to grow bone as quickly as possible,” he adds, “to help the body while it is still able to grow and replace the bone.”

The goal of the project is to show the feasibility of the process in large animals like sheep making it possible to conduct clinical trials, most likely among military personnel. However, the process is also expected to benefit civilians with traumatic bone injuries or disorders such as bone cancer that often require similar types of surgical repair.

More from Science & Enterprise:

- Engineered Tissue-Polymer Replacement Spinal Discs Developed

- NIH Award Supports Esophagus Tissue Implants from Stem Cells

- Trials to Test Stem Cell Treatments for Eye Injuries

- Tissue-Engineered Heart Chamber Model Developed

- Computer-Aided Bone Graft Process Devised with Stem Cells

* * *

RSS - Posts

RSS - Posts

[…] 3-D Printed Scaffolds with Stem Cells, Sensors Studied to Repair Bones […]