17 June 2019. University engineers and chemists are creating a more efficient material for separating carbon dioxide from emissions in power and industrial plants. The work of researchers from University at Buffalo in New York is funded by a $1.2 million award from the U.S. Department of Energy and $600,000 from NYSTAR, a state agency known formally as Empire State Development’s Division of Science, Technology, and Innovation.

A team led by Buffalo chemical and biological engineering professor Haiqing Lin is seeking a rapid solution for removing greenhouse gas emissions from some of the worst emitters of carbon dioxide, such as coal-fired power plants and factories making steel and cement. Current devices and systems for separating and capturing carbon dioxide, say the researchers, use thin filtering membranes that remove only a small fraction of the gas in the emissions.

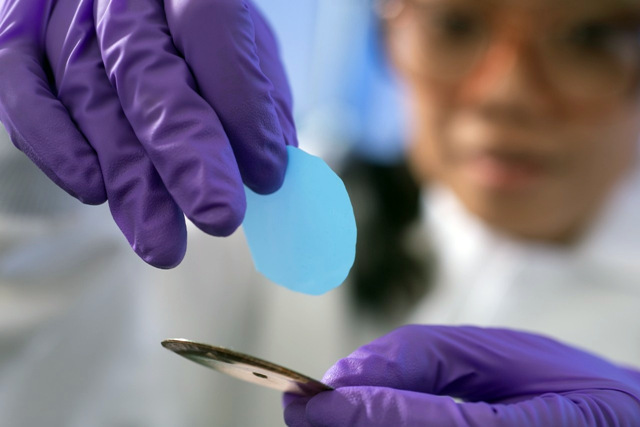

The researchers are developing a more efficient membrane that can be added-in directly to today’s power and industrial plant smokestacks. The new membrane, says the team, has polymers with additives that attract and capture much more carbon dioxide than membranes used today. Among the additives are metal-organic cages, chemical compounds linking inorganic and organic components dispersed through the polymer that attract more carbon dioxide from the emissions, but still allow other gases to easily flow through.

The new membranes aim to capture 90 percent of carbon dioxide emitted from coal-fired power plants, which the researchers say is 50 to 100 percent more than today’s membranes. The higher efficiency of the new membranes is expected to reduce the cost of capturing carbon dioxide to less than $30.00 a ton. The membranes produced at Buffalo will be tested by the National Carbon Capture Center in Wilsonville, Alabama.

“Carbon capture technology has the potential to make a huge impact right away when it comes to carbon emissions,” says Lin in a university statement. “Solar and wind are great, but it will take time for the world to increase capacity in these areas, and in the meantime, we are still burning fossil fuels.”

The membranes are expected to capture carbon dioxide in high concentrations, making it a potential raw material for other materials, including fuels. Co-principal investigator Timothy Cook, a professor of chemistry at Buffalo, studies catalysts helping transform carbon dioxide into carbon monoxide that can then be used to produce plastics normally requiring fossil fuels. “The carbon capture technology we’re working on,” says Cook, “is going to capture CO2 before it leaves the power plant, which is going to be much more efficient than trying to remove it from the atmosphere, where it’s much more diluted.”

The Buffalo project is part of a larger nationwide effort funded by DoE to quickly find carbon capture technologies. The larger project includes researchers from California Institute of Technology, Rensselaer Polytechnic Institute, Membrane Technology and Research Inc., and Trimeric Corporation.

More from Science & Enterprise:

- Economical, Sustainable Biochemical Process Devised

- Spin-Off Producing Commercial-Grade Graphene

- A.I.-Aided Processes Reduce Chemical Reaction Time, Waste

- Infographic – U.S., Canada Top National Carbon Footprints

- Jet Fuel from Carbon Waste Powers Virgin Atlantic Flight

* * *

RSS - Posts

RSS - Posts

[…] Efficient Carbon Capture Membranes Being Developed […]